There are numerous paint application techniques; you can employ brushing, spraying, rolling, dipping, flow coating, etc. In this article, we’ll focus on paint spraying using an air paint sprayer vs airless paint sprayer.

The machines differ in structure, spraying method/application, cost, operating pressure, the scale of operation, material viscidity, transfer rate, painting duration, and finish.

We’ll take a detailed look at the above differences, which machine fits a given situation (cost-benefit analysis), the pros and cons of the devices in question, the working mechanisms of both machines, and other relevant information regarding paint sprayers.

I’ll also mention a few top-notch brands of the machines named above.

My selection criteria are a blend of objectivity and subjectivity, i.e., based on customer reviews and personal experience.

Let’s begin by defining both machines.

What Is Air Paint Sprayer?

An air paint sprayer is also known as a conventional paint sprayer.

The above sprayer employs a low-pressure fluid stream blended with compressed air in the air cap to atomize and release paint in a controlled fashion.

It lays down low to medium viscidity paint for a refined finish and decorative painting.

There are three fluid-supply options for an air spray gun: suction-feed guns, pressure-feed guns, and gravity-feed guns.

Suction-feed guns have a cup attached under the front part of the gun; they handle small amounts of fluid, recurrent low-capacity color changes, and work at low production rates.

The suction results from airflow from the air cap, drawing fluid from the cup to the gun’s nozzle.

Pressure-feed guns are often fed by a hose from a pressure tank or a low-pressure pump; they are used commercially to move large volumes of paint through the system.

A gravity-feed gun has a cup fixed on the centerline to facilitate paint flow using gravitational force; they are ideal for tasks requiring small paint quantities like repairs or touch-ups.

What Is Airless Paint Sprayer?

An airless paint sprayer uses a high-pressure fluid supply to move and atomize paint; it employs hydraulics rather than compressed air.

An airless paint sprayer uses a high-pressure fluid supply to move and atomize paint; it employs hydraulics rather than compressed air.

It’s suitable for fluids of medium to high viscidity, gives a thicker/bolder finish, and has a high paint transfer rate.

The hydraulic force atomizes the paint by pushing it through an orifice.

When the fluid reaches the nozzle/spray gun tip, the high frictional force pulverizes it into fine droplets, which land on the substrate.

The pressure and tip orifice size dictate the appearance of your coating.

Paints with high viscidity require more pressure to lay down smoothly.

Differences Between Air Paint Sprayer and Airless Paint Sprayer

Both machines are used for painting, and all give high-quality finishes depending on the task; that’s the furthest their similarities can go.

Regarding their differences, which is the focal point of this segment, the talking points stretch far and wide.

I’d already mentioned the differentiating factors in the introductory bit of this article, so I’ll head straight for the analysis.

These are the differences:

Ease of Use

Ease of use, in this case, means the ability to manipulate the machine and what it feels like to use either device.

The air paint sprayer is easier to use than the airless version; this stems from their mode of operation.

The airless sprayer emits large volumes of paint at high pressure, while the air sprayer releases small amounts of paint at low pressure.

Emission of large paint amounts makes it challenging to apply the paint evenly and avoid paint runs.

It also makes it challenging to produce a patterned painting.

The discharge force also splashes paint off the substrate, so you have to get the distance right, i.e., the gap between the gun nozzle and the workpiece.

Lastly, the high pressure makes it difficult to paint hard-to-reach areas of the workpiece.

Airless paint sprayers have the dubious distinction of spitting paint when you release the trigger.

You must practice and master the habit of letting go of the trigger when you’re beyond the substrate.

If you release the trigger directly above the substrate, the spits will land on your workpiece and ruin your work.

On the other hand, an air paint sprayer is easy to use because it dispenses paint at low pressure; this gives you more control over where the paint lands and lets you make patterns during painting.

It also enables you to apply the paint evenly on the workpiece, and you can access hidden spots of the substrate.

Another point, an air spray gun doesn’t spit paint when you release the trigger.

You won’t go through the agony of learning when to let go of the said trigger during spraying.

The only challenge when using an air paint/conventional paint sprayer is that it tends to clog or plug at the tip.

It makes spraying even slower and distorts the spraying patterns/evenness.

You’ll therefore need to pause regularly to clear the clog.

To overcome the hitch above, use a twist tip; alternatively, you can use a slightly larger gun tip than the one susceptible to clogging.

A twist tip prevents plug formation by minimizing the downtime seeded by tip blockages when the machine is operational, while a larger tip size allows free paint voidance.

That said, the conventional sprayer/air paint sprayer gives a much better painting experience for beginners and amateurs; airless sprayers are ideal for professionals and experienced users.

Scale of Operation

The scale of operation, in this context, refers to the number of painting projects you have for the day.

For example, you may need to paint two houses, a motor vehicle, and a patio within 24 hours; that’s quite a handful and is considered a large-scale operation.

Operation scale is also viewed in terms of the size of the substrate.

For instance, painting a bungalow or a highrise building is different from painting a single apartment.

Airless paint sprayers are suited for large-scale projects like painting highrise buildings, numerous vehicles, big kitchen cabinets, etc.

It’s because they release more paint per unit time; this enables you to cover a large surface area in a single cycle.

Small-scale operations include painting household furniture, wood planks, metal sheets, boards, tables, and small kitchen cabinets.

These require a more specific paint application in smaller amounts; that’s what the air paint sprayer is made for.

It releases finer paint particles at a lower rate than its airless counterpart.

Small-scale projects also need precision painting techniques with better navigation; the air paint sprayer offers this with finesse.

Material Viscidity

Viscidity means the viscosity or flow properties of substances—the denser or stickier the liquid, the higher the viscidity, and vice versa.

Airless paint sprayers can handle more viscid substances, i.e., medium to high-viscosity fluids.

The air paint sprayer is ideal for less viscid material, i.e., low to medium-viscosity fluids.

Airless sprayers suit viscous paints because they use high pressure from hydraulic systems to initiate and sustain paint movement, while air paint sprayers use low pressure from air jets to propel paint.

From the above, you don’t have to thin paint before applying with an airless sprayer; the machine can generate enough force to lay it on the substrate.

For air paint sprayers, you have to thin the paint if it has high viscidity to enhance its application.

Finish

Finish means the appearance of the applied paint.

The air paint sprayer produces a finer and more refined finish. It is used for detailed painting projects.

The delicate finish is due to paint mixing with air and disintegration into atomized/misty droplets.

Conversely, poor paint-air mixing in conventional/air paint sprayers can lead to bubbles forming in the paint; this causes bumpy finishes containing trapped air.

However, this is quite rare as the machine is designed to work with air; unless the nozzles or spray gun tips are defective.

Paint from an airless sprayer flows at high velocity and does not mix with air; this leads to a high paint impact with the substrate and a coarser pattern.

The sprayer also causes paint spitting leading to drips and the formation of lines on painting edges.

Clean Up

Clean-up is imperative for all painting projects; it obviously comes last, but you have to prepare for it well both before and during painting.

Preparations involve removing surrounding objects and masking up immovable materials.

Airless sprayers leave a more messy working station than an air paint sprayer.

It’s due to their high discharge pressure, increased spattering, and low paint transfer efficiency.

High pressure will likely compromise your painting precision, so you’ll be somewhat inaccurate in your nozzle aim.

Increased splashing is due to the high landing force of the paint on the substrate.

Transfer efficiency is the proportion of paint delivered to the surface.

A large portion of paint from an airless sprayer will land in the environment surrounding the workpiece.

When it comes to cleaning the spraying machines, the air sprayer is more burdensome to clean.

You need to take apart the nozzle and fluid needle in the gun, along with the filter and cup inside.

Afterward, you’ll clean the parts separately, let them dry, then reattach them; this is tedious and time-consuming.

Airless sprayers only need flushing with clean water and washing the filters; this is straightforward and takes much less time.

Both sprayers have easy and challenging cleanup activities, but overall, the conventional paint sprayer leaves an easier cleanup task than its airless counterpart.

Transfer Rate

Transfer rate is also referred to as transfer efficiency in some texts; it is the fraction of paint that lands on the intended target and is usually expressed in percentage points.

The air paint sprayer has a transfer rate of about 90%, while its airless counterpart has a transfer rate of about 50%.

The higher the percentage, the lower the paint wastage.

So, if all factors are constant, i.e., the same kind of substrate, size, and environmental conditions, the air paint sprayer will need less paint to coat the said substrate than the airless paint sprayer.

It translates to reduced painting costs.

Cost

Let’s look at cost in terms of paint usage and purchasing price for both machines.

Regarding paint usage, the airless sprayer costs more as it has a lower transfer efficiency; this means a large proportion of the paint lands elsewhere or is swept away in the wind.

Additionally, the said sprayer releases pure and thicker paint, i.e., there’s no mixture with air, so it’ll definitely use large amounts.

On the other hand, an air paint sprayer has high transfer efficiency, meaning most of the paint hits the target rather than going to waste.

It also can’t work with highly viscous paints; you must first thin it.

Lastly, it mixes paint with air before directing it to the substrate. All of the above makes for a cheaper but cost-effective painting project.

Regarding purchasing costs for the machines, an airless paint sprayer costs more due to its working mechanism, expensive parts, and size.

It retails between $20 and $100, while the airless one ranges between $200 and $1000.

Operating Pressure

In the above case, pressure is the force required to move paint through the system and jet it to the substrate.

An airless sprayer operates at a higher pressure than an air paint sprayer.

It’s because the former relies solely on a hydraulic press mechanism for paint movement, while the latter uses pressure from compacted air and pressure from the machine for the same purpose.

We measure the operating pressure in psi (pound per square inch); the higher the psi, the higher the pressure.

Air paint sprayer/conventional sprayer operates at a pressure range of 15 to 70 psi, while airless sprayer runs at pressures up to 4000 psi.

Another reason for the stark difference is airless sprayers work on bigger projects than air paint sprayers.

The consequence of the above pressure differences is that the airless machine works faster but with lower accuracy than the conventional paint sprayer.

Note: You can adjust the operating pressure to your liking; remember to test on a scrap workpiece before painting the primary substrate.

Excess pressure leads to spray gun tip wear and overspray, while too little pressure causes an irregular spray pattern and takes a long duration to finish the task.

Performance

Performance refers to how well the machine can handle work; the indexing is based on the type of project and your expectations for the tool.

The air paint sprayer has better performance in producing different finish qualities.

It’s because its HVLP compressor offers alterable pressures than the hydraulic pumps of the airless model.

Furthermore, the HVLP turbines are easily movable

The airless sprayer performs better when you need to paint large surfaces over a short time or when you need to apply thick paint coats.

Conventional sprayers also outperform airless sprayers when vertical-spraying small projects.

Lastly, amateurs, beginners, and painting students show better performance and progress when using air sprayers than airless models.

It’s because of its excellent user-friendly profile.

From the user’s side, performance relies on knowing how to use the equipment and following all the painting protocols.

Safety Measures

Safety measures regard precautions that prevent harm to yourself, others, and the environment when using the equipment mentioned above.

It is a somewhat secondary difference between the two machines but still significant.

From the above discussion, it’s easy to surmise that the airless sprayer requires more safety measures than the conventional air sprayer.

It’s because of the high overspray, low transfer rate, and high discharge pressure.

Consequently, the airless machine releases more paint residue into the environment.

You, therefore, need to wear more safety gear and work in highly ventilated spaces when handling the airless sprayer.

The safety gear includes a respirator, safety goggles, latex or rubber gloves, and safety clothing.

You also need to ensure both machines are in good working conditions before use.

Inspect cables and electrical cords for any damages, check and replace any broken or worn-out parts, and take the machine on a dry run before getting to the main painting program.

Best Air Paint Sprayers

There are numerous conventional sprayers out there. If you purchase without prior research, you can easily get duped into buying a defective or substandard machine.

In this section, I’ll highlight some of the best air paint sprayers in the global market.

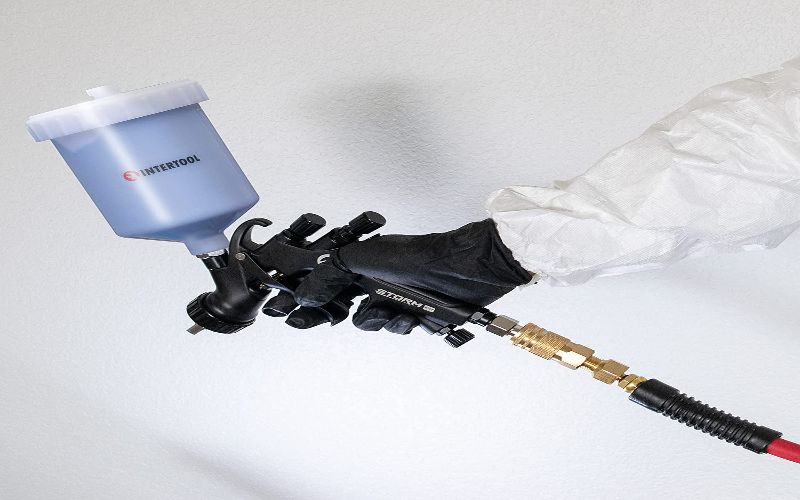

1. The INTERTOOL HVLP Air Spray Gun

The Intertool Air sprayer is a high-volume low-pressure machine for small to medium-sized projects involving woodwork, automotive parts, and home improvement.

The above machine is perfect for applying base coats, stains, water-based & polyester primers, thinned latex, clear coats, and other low to medium-viscosity coats.

This spray gun has the following desirable features:

This spray gun has the following desirable features:

- It produces minimum overspray to give a more precise and detailed finish.

- It is lightweight for improved mobility during operation.

- The spray gun is anodized to mitigate surface corrosion.

- The air sprayer is ergonomically designed with a smooth trigger engagement and adjustment knobs for comfort and superior control.

- Intertool spray gun comes with a 20-ounce paint cup; this holds enough paint/primer to prevent continual refills when painting.

- Its paraphernalia includes a quarter-inch swivel air hose inlet, an optional filter, a steel brush, and a spanner.

The above is one of the premium air spray guns I’ve ever come across. It does a marvelous painting job with transfer rates above 75%.

It costs more than other air sprayers, but it’s worth the price.

The spray gun is so good that you can never revert to cheaper air sprayers once you get a feel of what it offers.

Check Latest Price

2. Astro Spray Gun With Cup-Red Handle

Astro Pneumatic Tool Co. manufactures the above air paint sprayer.

The company is famed for top-notch air tools, including die grinders, impact wrenches, ratchets, cutoff tools, drills, and spray guns.

Speaking of spray guns, the Astro red handle version has the following standout features:

Speaking of spray guns, the Astro red handle version has the following standout features:

- It has a 1.8mm nozzle size to facilitate discharge of low to medium-viscosity primers/paints.

- The machine has an operating pressure of between 50-60 psi which is the required range for small to medium-sized projects.

- This spray gun has a mean air consumption of 7 to 12 cfm; this gives a perfect flow rate for optimal mixing with paint.

- It is a lightweight machine (2lbs); this makes it portable and easy to handle during operation.

- The air sprayer is all-purpose and easy to clean.

- This spray painter comes with a one-quart volume airtight cup.

- It’s easy to assemble, i.e., two-part construction.

- The spray gun has a unique air valve design and a characteristic red handle.

Best Airless Paint Sprayers

The airless sprayers are more modern than the air paint models.

Despite their belated arrival in the painting world, they’ve become popular due to ramped-up productions.

In this part, I’ll review the best airless paint sprayers available.

1. PowerSmart Electric Airless Paint Sprayer

PowerSmart is a registered trademark owned by Amerisun Inc., based in the American state of Illinois.

PowerSmart is a registered trademark owned by Amerisun Inc., based in the American state of Illinois.

It’s a big company with a rich legacy in making high-quality machines and equipment.

Powersmart itself covers lawn mowers, snow blowers, generators, garden tools, and power tools.

The company’s expansive portfolio and matching reputation speak a lot regarding its airless paint sprayer.

These are its advantages and qualities:

- It has a pressure adjustment knob for improved control.

- PowerSmart spray gun uses electricity from an AC source.

- The machine can attain high pressures up to 3000 psi for faster painting and for the convenience of painting large projects.

- The airless sprayer has a flexible suction tube that lets you work directly from a paint bucket.

- Its motor and gun body is conveniently separated to make its head lighter; this enhances mobility when painting.

- The spray gun has a regular nozzle size of 0.017 and a 517 tip. It makes it usable with various stains and paints for exterior/interior jobs.

- This electric spray gun is equipped with a stainless steel piston pump that can move unthinned paint effortlessly.

- PowerSmart airless sprayer is easy to use and clean, thanks to its simple assemblage design.

2. Graco Magnum Stand X5 Airless Paint Sprayer

The above airless sprayer is manufactured by Graco, Inc., an American company based and headquartered in Minneapolis, Minnesota.

Graco is a portmanteau of gray and company, and it was founded in 1926.

The company added airless spray guns to its portfolio in 1957 and went ahead to specialize in fluid and power handling machines.

The Graco magnum stand sprayer is among the best in their lineup owing to the following attributes:

The Graco magnum stand sprayer is among the best in their lineup owing to the following attributes:

- The machine can spray up to 125 gallons per year, so you can easily handle multiple or big projects.

- This airless sprayer can move highly viscid paints and primers without thinning.

- It has a total pressure control capability that allows you to dial in your desired pressure setting to control the spray speed and achieve a smooth finish.

- THE Graco X5 sprayer has a piston pump with a powerful thrusting pressure of up to 3000 psi for efficient atomization and paint release.

- It can support 10 TrueAirless® spray tips from which you can select the best tip size and pattern for your project.

- This airless sprayer has a flexible suction tube that lets you spray directly from a one or five-gallon bucket.

- The spray gun works perfectly with long hoses up to 75 feet; this allows a broader reach and increased mobility when painting.

- It has a sturdy stand to stabilize the machine when operational.

- The machine has a power flush clean-out adapter that you can easily hook up to a garden hose for simple and fast cleanup.

- Lastly, it has an excellent value for money profile as the machine does way better than its cost.

Pros and Cons of Air Paint Sprayer

As usual, all machines have advantages and disadvantages.

However, the benefits must outweigh the downsides for the tool/device to be rendered useful.

These are the pros and cons of air paint sprayer:

Pros

- It’s cheaper than airless sprayers

- The machine is portable

- It economizes paint due to its high paint transfer profile

- Air paint spray gun is safe to use

- It gives you more control over paint application

- This sprayer does not spit paint when you release the trigger

- An air paint sprayer does not result in paint drips

- The equipment gives a fine finish

- It uses less pressure than an airless spray gun to atomize paint, hence minimal energy wastage

Cons

- It is prone to tip plugging/clogging

- The machine can’t work with thick paint; you have to thin the paint

- The air sprayer is slower than its airless counterpart

Pros and Cons of Airless Paint Sprayer

It’s the same story for the airless paint sprayer; it has both advantages and drawbacks.

Some of the points for the two machines are almost mutually exclusive, i.e., a plus for one machine is a snag for the other.

Here are the pros and cons of airless paint sprayer:

Pros

- The machine doesn’t need an air compressor.

- It is faster than an air spray gun, hence better suited for more extensive projects.

- This equipment applies thicker paint coats.

- Air spray guns are easy to assemble and disassemble.

- This tool is easy to clean.

- It produces a finish with no air bubbles/fish eyes because the paint doesn’t mix with air during discharge.

- The machine eliminates the need for paint thinning before application; its high pressure can handle highly viscous paints.

Cons

- It is comparatively more expensive than the air paint sprayer.

- An airless sprayer wastes more paint due to the high overspray (it has a 50% transfer rate).

- The high overspray causes environmental pollution and poses a risk of respiratory infections.

Apart from the above, the paint sprayers have general advantages and disadvantages over other spraying techniques. They are as follows:

Pros

- They produce faster drying times

- Using sprayers is less tedious than other techniques; the mechanization makes it easier for the user

- The machines lay down paint evenly without brush marks

- Paint sprayers are fun to use

- The spray guns are less messy

- Spraying machines cover larger surface areas per unit time, enabling timely finish for big projects

- Paint sprayers offer a wide variety of patterned finishes courtesy of the spray gun tip design

Cons

- Spray painting is only feasible under calm weather; even slight breezes significantly undermine their efficiency

- Paint sprayers are not ideal for highly detailed painting like in artistry

- High maintenance costs for the machines: regular oiling, replacing worn-out parts, and cleaning

Can You Use a Paint Sprayer With an Air Compressor?

A compressor is a mechanical gadget that raises gas pressure by decreasing its volume.

Pressurized air can atomize and spread fluids like paint when let out. By the same token, can you use a paint sprayer with an air compressor?

The answer is yes! The air compressor is actually an integral part of paint sprayers.

It is a special type of gas compressor that transmutes power into potential energy; this energy is stored in the form of pressurized air.

To use the air compressor, you have to meet the following:

- Your machine needs to be an air paint sprayer: Not all paint sprayers use pressurized air to emit paint. You can’t use the air compressor if your sprayer uses a different mechanism like hydraulics.

- The paint must have proper viscidity/thickness: air compressors only facilitate the atomization and dispersion of thin to medium-viscosity paints. If the paint is too thick, you must thin it before letting it into the machine. Otherwise, the air compressor won’t work efficiently.

- Compressor-sprayer compatibility: The spraying device and the air compressor must be compatible so that the compressor fits snugly without any leakages or loose connections. You should clamp it on easily and tighten it before use. Only then will the sprayer and compressor work collaboratively.

How Does an Air Compressor Work?

To know how a conventional sprayer works, you must first understand how an air compressor works.

The air compressor changes power, using a diesel/gasoline engine or an electric motor, into potential energy in the form of compressed air.

By one or multiple means, the compressor forces more air into the storage vessel, increasing its pressure.

When the vessel’s pressure reaches its upper limit, the compressor turns off. The pressurized air is then confined to the tank for use.

Releasing the compressed air provides kinetic energy (air in motion), which atomizes and spreads paint in the case of an air spray gun.

The tank depressurizes until it reaches its programmed lower limit, at which point the air compressor turns on to refill/re-pressurize the tank.

How Do You Connect a Paint Sprayer to An Air Compressor?

The paint sprayer is designed for painting, while the air compressor facilitates the paint application.

The two devices have to work in concert.

So how do you connect a paint sprayer to an air compressor?

Requirements

- A high-pressure hose

- A suitable air compressor

- Safety gear: a respirator, face mask, and safety goggles

- An air paint sprayer

- Spray gun attachments: connectors, filters, and regulators

procedure

Gather the above equipment in readiness for setting up the compressor.

If you are using a new machine, ensure all the accompanying implements come in sealed packages.

It gives assurance of an excellent working condition, i.e., no leakages, breakages, or rusts.

Next, put on all the safety gear to prevent injury.

Then, join the air paint sprayer attachment to the compressor using the high-pressure hose.

The best hose length for an air paint spray gun ranges from 25 to 50 feet.

Shorter hoses will tether you to short reaches, while longer ones reduce the air pressure from the compressor.

Also, affix the connectors and regulators to the appropriate attachment sites.

Fit according to the user’s manual; each spray comes with its unique guide. Follow this to the latter.

Check your paint sprayer for the volume of airflow required in CFM (cubic feet per minute) and ensure the compressor delivers at least that load.

Pull the sprayer trigger to check whether the regulators are working; these measure the air pressure from the compressor in PSI (pounds per square inch).

Turn the adjustment knob on the compressor or the spray gun to check the integrity of the compressor; the psi readings should change according to your calibrations.

If your compressor passes all of the above tests, it is fit for its purpose.

Here’s a Video On How to Connect a Paint Sprayer to an Air Compressor:

How Does a Compressed Air Paint Sprayer Work?

We’ve already seen that an air paint sprayer needs an air compressor to function and even discussed how to connect the compressor to the machine, plus the working mechanism of an air compressor.

So now, how does a compressed air paint sprayer work?

The working mechanism of the spray gun depends on the gun type, but the principles are similar.

Feeding an air spray gun is three ways: gravity feed, suction feed, and pressure feed.

Each method injects air into the paint to disintegrate/atomize it to the desired finish character.

The main difference is how the paint flows into the gun for air to be injected.

For example, suction paint sprayers work by drawing paint through a venturi to the fluid nozzle.

Gravity spray guns use cups attached to the top of the fluid nozzle joint; when you pull the gun trigger, the needle draws back to enable paint flow via gravitational force.

Pressure-feed paint sprayers use external pots (pressure cisterns); these are pressurized to force paint into the gun, followed by an injection of air.

How to Use a Paint Sprayer Connected to An Air Compressor

Now you know the working principle of an air paint sprayer, how an air compressor works, and how to connect the two.

That brings us to the last and vital segment of this discussion, i.e., how to use a paint sprayer connected to an air compressor.

I thought starting with the other subheadings was crucial to make this last bit easier to comprehend.

Requirements

- Safety gear: rubber or latex gloves, a respirator, and safety glasses

- A compatible air compressor

- Spray gun accouterments: regulators, filters, connectors

- Paint

- Power source

- Paint thinner

- Tarp

Procedure

Start by removing all materials that you don’t intend to paint.

Next, cover the floors, walls, and immovable materials using a tarp.

Then, wear all the safety gear and ensure adequate air circulation in your working area.

Afterward, connect the air compressor to the paint sprayer using the procedure and precautions discussed earlier.

Then, thin the paint to the appropriate thickness using the thinner and put it into the paint cup.

Clamp the cup to the spray gun and test on cardboard or any scrap workpiece.

Testing will guarantee you the right spray gun tip size for even and patterned painting.

If you’re not impressed with the quality of the finish, you can make the following adjustments for a better outcome:

- Change the air pressure from the compressor

- Switch between the spray gun tips

- Thin the paint further or make it thicker as needed

- Adjust the knob on the spray gun to fine-tune the paint and air mixture for a more delicate sprinkle/spray

- Apply the paint in fluid and smooth motions back and forth at a constant pace

- Overlap each paint cycle for an even coat

If you check all of the above boxes, your finish will look exquisite, and you can proceed to paint the target substrate; remember, this was a test run on cardboard.

Spray your workpiece using two or three coats as needed and let each layer dry before applying another.

When done, please switch off the sprayer and disassemble it in readiness for cleaning.

Clean according to the manufacturer’s specifications; each machine has a unique cleaning protocol.

When the paint dries, remove the tarps and return the previously-removed materials.

Note: It’s important to know that high pressure does not confer the best paint finish; it only goes so far.

You have to find a balance between pressure and the volume of paint.

Too much pressure makes the spray gun release more air than paint, while too little pressure releases large spray particles.

That’s why I advise you to always test before use.

Conclusion

To conclude, the painting world has significantly evolved! In the past, people used specially made sticks to apply paint, leaves, and palms.

Then came the era of rags, paint brushes, paint rollers, flow coating, and dipping.

The most modern technology is using paint sprayers; there are numerous types, but the above article pivots around…

Air Paint Sprayer Vs Airless Paint Sprayer

To abridge, the differences are in the following aspects:

- Ease of use

- Scale of operation

- Material viscidity

- Finish

- Clean up

- Transfer rate

- Cost

- Operating pressure

- Performance

- Safety measures

I’ve discussed how the above differences make the sprayers unique, how they influence their functionality and the appropriateness of the two machines in apposition to various situations.

I’ve also touched on the pros and cons of the devices named above and a few best brands on both sides.

Additional highlights include using a paint sprayer connected to a compressor and the mechanism of action of a compressed air paint sprayer.

I’ve always had a keen interest in spray painting, so I urge you to read carefully and acquire one or more of the brands I’ve mentioned.

Rest assured, you’ll get the best painting experience.