Knowing how to thin paint for spray gun ensures you get the perfect finish for your spray painting project!

Before applying paint with a spray gun, you must ensure it has the right viscosity and consistency.

If it is too thick, you have to thin it; if it’s too runny, you should make it thicker.

Most paints are manufactured thick because it is easier for the user to thin paint than to make it thicker.

Therefore, it’s crucial to know how to modify flow properties so that you can apply the knowledge to your paint.

This article has many paint types and applicators, but I’ll center on how to thin paint for spray guns.

The general thinning process involves paint stirring, pouring small amounts into a separate mixing container, adding the thinning agent, and mixing.

You then repeat the above steps until you attain the desired viscosity.

If you mistakenly put in too much thinner, simply add the thick original paint to the mixture to remedy the situation.

The type of paint you’re thinning dictates the thinning agent you’ll use.

We use water for water-based paints and mineral spirits, turpentine, or acetone for oil-based paints.

More learning points included in the writeup are:

- What to use to thin paint for spraying

- The mixing proportions of paints with thinners for spray guns

- How to mix paint for a paint sprayer

- Whether or not to use acetone as a paint thinning agent

- How to use a spray gun

- Contrasting a lacquer thinner with a paint thinner

The above subtopics make the review the right information hub for the title. Read it wholly to sharpen your paint thinning and spray painting techniques.

I’ll lay out the foundation by starting with the definitions.

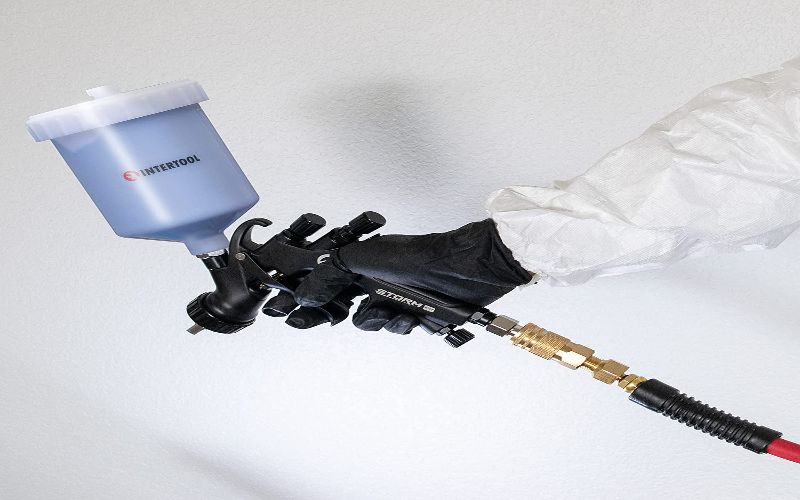

What Is a Spray Gun?

There are various ways of applying paint. They include brushing, dip coating, spraying, rolling, flow coating, etc.

There are various ways of applying paint. They include brushing, dip coating, spraying, rolling, flow coating, etc.

In congruence with the article’s heading, let’s look at a paint spraying machine called a spray gun! What exactly is a spray gun?

A spray gun is a device that disperses coating materials (varnish, paint, ink, etc.) into a mist that lands on the targeted surface.

The most common models use either pressurized/compressed air or hydraulic pressure systems to disintegrate and channel the paint.

Spray guns are an improvement of airbrushes; you can tell the two apart using their size, handling, and spray patterns produced.

Airbrushes are handheld and ideal for detailed painting jobs, as in fine arts and photo retouching.

Spray guns are bigger and often cover large surfaces like car bodyworks, kitchen cabinets, metal sheets, walls, etc.

Spray guns have interchangeable heads/tips that produce varying spray patterns and can be handheld or automated.

Advantages of Spray Gun

There are many forms of spray painting; the spray gun is more popular due to its unparalleled benefits.

Here are some of the advantages of a spray gun:

- The technique is less messy

- Spray guns produce even coatings and leave no brush marks

- This tool allows you to dial in your desired pressure for painting

- It leads to low production costs

- Spray guns need less effort than other painting tools because it is motor-driven

- The atomization of paint by a spray gun speeds up the drying times

- It can easily paint on rough and smooth surfaces

- The machine covers large surface areas per unit of time; this enhances timely project completion

- A spray gun enables you to achieve several spray patterns by changing the tips and manipulating the fan control

- The machine is ergonomically designed for comfort and a delightful user experience

Cons

- The machine results in an orange peel finish from excess paint application, incorrect machine setup, and rapid solvent evaporation.

- It wastes paint and pollutes the air due to overspray.

- Spray guns are efficient only under calm weather; wind or even a light breeze exacerbates the overspray problem.

What Can I Use to Thin Paint for Spraying?

Paint thinning is lowering a paint’s viscosity by adding thinning agents.

It makes thick paint lighter, runnier, easier to spray, and has better surface coverage. So, what can I use to thin paint for spraying?

What to use depends on the type of paint you’re handling. If it’s water-based paint, use a water-borne thinner; if it’s oil paint, use an oil-based thinner.

Likewise, if it’s lacquer paint or shellac paint, use lacquer and shellac thinner, respectively.

Do not mix up or mismatch the thinners with the paints.

Mismatching, in this context, means = for example, using oil-based thinner to thin out water-based paint. It just won’t work!

These are the best thinning products for various spraying paints:

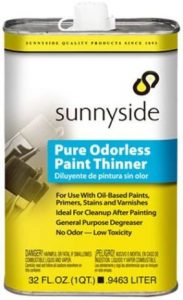

Sunnyside Paint Thinner

Sunnyside Corporation, founded in 1893, manufactures the above thinner.

Sunnyside Corporation, founded in 1893, manufactures the above thinner.

The company also manufactures paint removers, solvents, additives, and cleaners for hardware and paint retailers.

This company has always been under exceptional family leadership, making it the best in its craft.

The Sunnyside paint thinner is one of their best paint modifying products.

Its advantages and features include:

- It has a low odor

- The thinner comes at an affordable price

- It’s also excellent for thinning stains and varnishes

- The thinner has high solvency and degreasing power

- This product is easy to use

- Sunnyside thinner comes in 32 fl oz containers

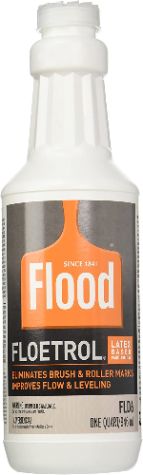

Flood Floetrol

Flood® manufactures the above product; they are renowned for their top wood care products.

The products serve preservative, decorative, protective, and paint modification roles.

Each of their products meets the needs of professionals, DIY enthusiasts, and trainees by delivering quality outcomes.

Each of their products meets the needs of professionals, DIY enthusiasts, and trainees by delivering quality outcomes.

One of their products is flood floetrol. It’s not a water-based paint thinner per se, but it serves a similar role.

It has the following benefits and features:

- Floetrol fortifies latex and acrylic paint to improve their performance

- It enables latex paint to discharge similarly to oil-paints

- The agent has a wide coverage of up to 300 sq feet

- Floetrol is easy to wash or remove using soapy water

- The agent prevents piston freeze-up and tip clogging when spraying

- It improves the leveling and flow of water-based paints

- Flood floetrol is easy to use

- The product comes at a budget-friendly price

How to Thin Paint for Spray Gun

Paint thinning appears daunting to the inexperienced and the uninitiated.

In a real, practical sense, It’s pretty easy. Follow my lead as I take you through how to thin paint for a spray gun.

The thinning processes vary based on the type of paint. We have oil- and water-based paints with different constituents, consistencies, and flow properties.

It means the thinning agents and ratio of paint to thinner vary for the two groups. Here is an in-depth look:

How to Thin Oil-Based Paint

Water is contraindicated for thinning oil paints. Oil and water are immiscible because oil is an organic solvent while water is inorganic.

Instead, use paint thinners like mineral spirits, turpentine, and acetone, all of which are organic solvents.

The thinning cost for the paint mentioned above is cheap if you factor in the ease of application and time-saving effects it brings to the drawing board.

Requirements

- Mixing containers

- Stirring sticks

- Measuring containers

- Safety gear (respirator, goggles, and gloves)

- Pant thinner: Mineral spirits or turpentine

- Paint strainers

- Drop cloth

- Oil-based paint

- A plastic or glass funnel

- Paper towels

Procedure

First, set the stage by ventilating your working station and laying down the drop cloth.

Then, go through the datasheets and read the instructions printed on the paint and thinner containers. Afterward, don the necessary safety gear.

Next, open the oil paint can and stir it using the stirring stick.

Pour some of the paint through a paint strainer into the clean mixing container and close the main paint can.

Straining removes any solids that might be present in the paint.

Measure the resulting filtrate by pouring it into a measuring cup or container through the glass funnel. Note down the reading.

It’s best to use the paint only in small portions because some have short pot lives following mixing.

Pot life is the duration that mixed paint is viable for application; it’s also known as its working life.

Then, open the turpentine or acetone and stir or swirl to make it uniform. Measure according to the specified proportions and add this to the paint.

The standard mixing ratio is 1:4 or there about. You can adjust the said ratio depending on the spraying machine and scale of operation.

Then, stir thoroughly with a mixing stick.

Add the thinner and paint to the mixing container until you get the right consistency.

That’s all you need to do! Your paint is now thinned.

How to Thin Water-Based Paint

Water-based paints require only water or water-soluble solvents for thinning.

Turpentine is insoluble in water, so you can’t use it to thin water-borne paints.

It can only dissolve in oily (lipophilic) solvents, like oil paints.

Thinning water paints improve their flow and ease of application. It also keeps them in a liquid state throughout the painting project.

Requirements

- Clean water

- Stirring rods

- Drop cloth

- Paint strainer

- Water-based paint

- Clean mixing containers

- Safety gear (a respirator, latex gloves, and safety goggles)

- Measuring container

- Glass or plastic funnel

- Paper towels

Procedure

First, read all the instructions written on the thinner and paint containers.

Then, aerate your working room to improve airflow. It prevents intoxication from inhaling paint when thinning.

Lay down a drop cloth or old newspapers to avoid spillage or spattering to the floor and surrounding areas when mixing.

Then, put on the appropriate safety equipment.

Afterward, open the water paint can and stir it with a stirring rod.

Pour a portion of the paint into a clean mixing container through a paint strainer; close the main paint can soon after.

Straining removes any solids and globules present in the paint.

Pour the filtrate into a measuring container and record the amount. Use a glass funnel to transfer the filtrate into the measuring cup.

I recommend you use only small amounts of water-based paint as they have short pot life after mixing.

Pot life is also known as the working life of paint; it is the period during which paint is viable for use.

Next, measure and add water to the paint according to the specified amounts.

The mixing ratio for water and paint is not fixed for all water-based paints; you can always adjust according to the type of sprayer and the size of your project.

Stir the mixture with a stirring rod to make a homogeneous solution.

Add water to the paint till you attain the desired consistency.

There you go! Your water-based paint is now thinned.

Here’s a Video On How to Thin Water-Based Paint:

What Is the Ratio of Paint to Thinner for Spray Gun?

Paint should discharge smoothly from the gun and land evenly on the substrate; this can only happen when you mix properly.

So, what is the ratio of paint to thinner for a spray gun?

The standard ratio of paint to thinner is 4:1.

However, these proportions vary depending on several situations, including the spray gun you’re using, the paint type, and the substrate.

Here is the breakdown:

Type of Spray Gun

There are two main spray gun types for spray painting, i.e., the airless sprayer and the HVLP (High Volume Low Pressure) sprayer.

The airless sprayer moves paint at high pressures using hydraulic mechanisms that don’t involve atmospheric air.

Therefore, it can move and apply thick paint easily.

In this case, you can opt to add only small quantities or no amounts of thinner.

If the paint is water-based, use paint to thinner ratio of 7:1. If it’s oil paint, mix paint with thinner in the ratio of 5:1.

These are only approximations; the best approach is to follow manufacturer-recommended values or whatever fits your substrate.

You can always test on scrap material before proceeding to the main substrate.

HVLP spray guns pump large volumes of paint at low pressure.

Therefore, they need more thinner for the same paint compared to the airless sprayers.

It improves paint flow through the machine and minimizes wastage.

If it’s water-based paint, I recommend a paint to thinner ratio of 7:2. If the paint is oil-borne, mix paint to thinner in the ratio of 7:3.

Again, check the labels first or approximate by physically testing on scrap substrates.

Paint Type

The paint type also determines the paint and thinner percentages making up the solution.

Paints are generally classified into two, i.e., oil paints and water-based paints.

The oil-borne paints are usually thicker/more viscous than their water-based counterparts. It means the former requires more thinner than the latter.

Paint to thinner ratio for water-based paints is 5:1. For oil paints, the ratio is 4:1.

However, the viscosities differ based on the manufacturing company and the additives contained in the paints.

Check the manufacturer’s specification and personal preference as a gauge for the most appropriate ratios.

Substrate

The substrate determines the paint/thinner ratio in two main aspects: the surface area and the material.

On the surface area, large-sized substrates require thin paint for better coverage and reduced costs.

The thinned paints flow easily and spread much better than the thicker versions. Here, I recommend a paint to thinner ratio of 4:1.

On material, smooth and impervious surfaces need thicker paint than rough, porous substrates.

The low viscosity of thinned paint makes it flow off a smooth surface upon application while thicker paint sticks.

Also, thin paint fills the pores on rough substrates better than thick paint and ensures little paint wastage.

For the smooth surface, I prescribe a paint to thinner ratio of 6:1, while for the rough surface, I advise a ratio of 4:1.

How Do You Mix Paint for a Paint Sprayer?

You must mix paint to modify its viscosity and make it more usable with the gun. But, how do you mix paint for a paint sprayer?

Procedure

Step 1: Gather Your Tools

Collect and set up the following apparatus:

- Paint

- Paint sprayer

- Thinning agent

- Paint strainer

- Test board

- Clean water

- Safety goggles and a face mask

Gathering the required materials avoids unnecessary interruptions once you’ve started working.

Step 2: Paint Vs. Thinner Selection

Paint mixing depends on the paint you’ve settled for, among other factors. They have different constituents, viscosities, and physical & chemical properties.

Alkyd and linseed oil paints will only mix with organic solvents like turpentine, acetone, and mineral spirits. It’s because they are oil-based paints.

Acrylic and latex paints will only mix with water and floetrol. It’s because they are water-based paints.

Note: You don’t have to thin all paints before loading them into spray guns.

Some of them come with the right consistency for direct application, or the sprayer could have sufficient pressure to apply the paint without thinning.

Also, excessive thinning undermines the paint’s quality and adhesive power.

Step 3: Put on Protective Gear

It’s essential to wear the necessary safety gear to protect yourself from harmful paint and thinner fumes during mixing.

If you don’t put on the safety equipment, you risk respiratory problems, allergic reactions, and skin and eye irritations.

Also, ensure you ventilate your working room for proper air circulation.

Step 4: Stirring

Then, open up the paint can and stir the contents using a mixing stick.

Stirring dissolves congealed paint at the bottom of the container; this mixes the paint solution to achieve homogeneity.

Step 5: Paint Straining

Then, take the stirred paint and pour some of it into a measuring cup via a paint strainer. Put back the lid of the original paint can.

Straining removes insoluble lumps and foreign particles from the paint, making it smooth.

The lumps can clog up the sprayer orifice and channels, leading to undue interruptions and uneven finishing.

Step 6: Thinning

Next, thin the paint by adding the most appropriate thinning agent.

If it’s water-borne paint, add water; if it’s oil paint, add mineral spirits, turpentine, or acetone. Mix the two in the specified ratio.

Stir the paint thinner mixture thoroughly using the mixing stick. If you add too much thinner, the paint will become excessively runny.

The solution to the above is simple: add more of the original paint and stir again until you attain the required viscosity.

Use small amounts of paint and thinner to avoid mistakes and make the correction easier just in case you miscalculate the ratios.

Using paint in small proportions also enables you to work with its pot life.

That’s all you need to mix paint for a spray gun.

You can now gauge the integrity of the mixture by loading it in a spray gun and spraying it on a test board before proceeding to the main substrate.

Here’s a Video On How to Mix Paint for Spray Gun:

Can You Use Acetone as Paint Thinner?

There are numerous agents you can add to paint to alter its properties. However, can you use acetone as paint thinner?

Absolutely yes! Acetone is an excellent paint thinner. However, its use for the above purpose is limited to oil-based paints.

Adding acetone to water-borne paints undermines their adhesion.

Acetone falls under the same class of paint thinners as turpentine and mineral spirits.

The advantage of acetone over other oil-based thinners is that it is highly volatile; it quickly evaporates to enhance paint drying.

Its drawbacks are it has a pungent odor and is highly flammable; these pose both a health risk and a fire hazard.

However, modern formulations are scented and laced with fire-retardants.

Other related uses of acetone include:

- Thinning of polyester resins

- Dissolving two-part epoxies before they harden

- For thinning varnishes

- For heavy-duty degreasing to prepare metals for painting or soldering

- For removal of rosin flux following soldering: this prevents corrosion, dirt adhesion, and electrical leakage

- For glassware rinsing to remove solids and residue before the final wash

- Acetone is the main constituent in cleaning agents like superglue and nail polish removers

How to Spray With a Spray Gun

Knowing how to thin paint and the mixing ratios is of little or no value if you don’t know how to spray with a spray gun. I’ll show you just that in this segment.

Proper spray gun use involves setting it up correctly, mixing and loading the right paint into it, testing on a scrap substrate, and final painting on the main substrate.

These are the details:

Setting Up the Spray Gun

Before preparing the spray gun, I’ll share some crucial information; a siphon-feed spray gun wastes too much paint. It’s down its operating mechanism.

The paint holder is positioned below the nozzle, so the machine sucks up the paint delivering it to the nozzle directly. Thus, I contraindicate it for spray painting.

I often encourage the use of HVLP spray guns to spray paint. Their paint cups sit above the nozzles, which is a gravity-feed system.

Their operating mechanisms result in less overspray, no paint wastage, and minimal environmental contamination.

The spray gun has four main adjustment knobs that you must fine-tune for correct usage.

They are the fan control, nozzle/horn adjustment, air volume adjustment, and paint volume control.

I’ll discuss the above controls in the sprayer testing part a few steps below.

The only control dial I can cover here is the regulator. It’s not always a part of the HVLP spray gun.

The regulator is usually connected to the air compressor, purchased separately from the spray gun.

Regulators measure and control the air pressure from the compressor, calibrated in pounds per square inch (PSI).

Other than the one coming with the air compressor, I advise you to acquire an external regulator and affix it to the air inlet valve close to the spray gun’s handle.

It lets you know the precise air pressure used for atomizing paint.

I advise so because the air pressure measured at the compressor is usually lower when it gets to the spray gun, mainly when using long hoses (above 50 feet).

Again an external regulator allows you to achieve the air pressures prescribed for the spray gun if the air compressor works at high pressure magnitudes beyond the HVLP gun.

Join the external regulator with the spray gun inlet. This attachment rules out the need to use the air volume adjustment.

Then, couple the spray gun to the air compressor and turn on the machine.

Tune the pressure to the approved range for painting your substrate. You can only tune this when the machine and compressor are on.

The optimal air pressure range for HVLP guns is 20 to 30psi.

When you get to the set mark, turn off the machine and don’t interfere or change the setting as you’ll use this pressure value for the final painting.

If you set the pressure too high, there’ll be a high paint rebound effect and too much overspray, leading to paint wastage.

If you set the pressure too low, there will be inadequate atomization, and the machine will release larger paint globs.

It leads to droplet-like patterns, which are unsightly on a painted surface.

The next stage is paint mixing, which I’ve already discussed in a few segments in the article.

Refer to “How do you mix paint for a paint sprayer?” for more details.

Up next is testing the spray paint pattern and integrity.

The Test Run

Use a scrap material piece to test the paint. It’s best to use a scrap substrate of the same make as the main one for a more accurate assessment.

Mount the cup filled with paint on the sprayer to start the trial. Tune the following adjustments/controls when testing:

The nozzle horn: This is located at the front part of the gun (the airhead area).

Adjust it to direct the orientation of the ejected paint stream. It allows the paint to outspread vertically or horizontally.

Fan control: This is situated behind the paint cup at the back end of the gun. It controls the broadness and shape of your spray pattern.

If it’s screwed in or closed, it gives a narrow, concentrated circular pattern.

The more you screw it out/open it, the more fanned out your pattern becomes, and the finish also appears lighter.

The fan control dictates paint coverage. When painting the broader parts of the substrate, I advise you to pull the adjustment further out.

When working on the workpiece’s smaller and more intricate sections, screw in or tighten the fan adjustment for a narrower pattern.

The fluid/paint control knob: This is found just below the fan control.

It regulates the amount of paint coming out of the paint holder. The further out or looser it is, the more the paint is discharged.

If you screw it in too tight, insufficient amounts of paint are ejected. The paint will go lightly and unevenly on the substrate due to disproportionate mixing with air.

It forces you to go over the workpiece several times in an attempt to lay down a thicker coating; this wastes time.

On the other hand, if you loosen the knob too much, there will be excess paint release. It leads to paint runs, less control and causes wastage.

A rule of thumb is always tuning the paint control from tight to lose, as adding more paint is more convenient than taking off the excesses.

The air adjustment knob: This is located on the lower section of the HVLP sprayer handle. It controls the air supply.

An external regulator bypasses the air control, so you don’t need to use it.

Don’t alter the regulator pressure, as we had already set the required levels when getting the spray gun ready.

I advise you to make the above alterations when testing on scrap material, not on the main substrate.

After everything matches up well, proceed to the painting step.

Painting

Hold the sprayer 8 to 12 inches from its surface when spraying a substrate.

Make sure the spray gun’s nozzle points perpendicularly to the target.

The best application technique is moving your hand a moment before discharging the paint and keeping it in motion for one second after you’ve covered a given section of the substrate.

It precludes the accumulation of paint at the starting points and ends of each painting cycle; this paint collection is due to spitting by the spray gun when you pull and release the trigger.

Another crucial piece of advice is to overlap each painted segment by 50%.

This ensures you don’t miss any substrate parts and adequate paint layering.

I recommend you apply a light first coat. It makes it easier to correct mistakes and prevent paint runs. Remember, rectifying lightly painted surfaces is simpler than heavily painted ones.

Let the first paint coat dry for the specified time, then follow with a second and third coat.

Apply thicker second and third coats and let them also dry before proceeding to the next step.

Then, remove the newspapers or drop cloth and other materials you covered.

That’s all you need to know to paint successfully with a spray gun.

If you follow the procedures mentioned above, everything will turn out well.

An important post-painting practice is clean-up.

It needs a thorough approach to avoid damaging the sprayer and to make it ready for subsequent painting projects.

Difference Between lacquer Thinner and Paint Thinner

Paints differ in many aspects; so do thinners. The thinning agent has to be compatible with the paint’s physical and chemical characteristics.

In this section, I’ll discuss the difference between lacquer thinner and paint thinner.

Lacquer thinner is also referred to as cellulose thinner!

It’s usually a combination of solvents that can dissolve several plastics and resins contained in modern lacquer.

Initially, lacquer thinners consisted of ketones (like methyl ethyl ketone and acetone), ethers (e.g., glycol cellosolves), and alkyl esters (such as amyl acetate and butyl), aromatic hydrocarbons (like toluene), and/or alcohols.

Modern lac thinners primarily consist of acetone and small amounts of aromatic solvents; they are so formulated to comply with the set VOC regulations.

It makes the thinners less harmful to the environment.

A thick lacquer is more challenging to apply as it blocks the sprayer’s channels. It also consumes more energy to move the thick paint through the gun.

If you manage to discharge the paint, the finish will be pitted, bumpy, and with an orange-peel texture.

The quick solution to all of the above is using a lacquer thinner.

When to Use Lacquer Thinner

- To reduce the viscosity of lacquer paint

- For cleaning accidental lacquer paint spills

- To clean the spray gun and other paint application tools

- To remove oil, grease, and ink stains from surfaces

- For removing water-based paints during makeovers

Paint thinners are solvents for thinning oil-based paints.

Some are flammable with a flash point of around 104°F (40°C), similar to many popular charcoal starter brands.

The most common paint thinner solvents are:

- Turpentine

- Acetone

- Mineral spirits/white spirit

- Naphtha

- Dimethylformamide

Less commonly used solvents include xylene, ethyl benzene, and butanol.

Overexposure to paint thinner vapors is a health hazard, especially to people with respiratory problems and pregnant women.

Therefore, wearing a face mask and safety goggles is advisable when using the said agents.

Another problem that plagued paint thinners was their abusive use and fondness of society’s indigent and teenage cohort.

Modern formulations don’t have addictive odors and ingredients to prevent misuse.

The manufacturers also encourage users and caregivers always to store the agents safely away from children.

When to Use Paint Thinner

- To reduce the thickness of oil paints for easier application

- To prevent spray gun clogging and orifice blockage by improving paint flow through the sprayer’s channels

- For cleaning paintbrushes and other application tools

- To clean up oil-paint spills

- For cleaning oily and greasy stains from surfaces

- To give the oil paint a broader surface coverage per unit time.

Conclusion

To conclude, paint thinning is an effective practice that simplifies its application in myriad ways.

It’s even more critical when using a spray gun to lay down the paint. It enables uniform atomization and a smooth discharge of paint throughout the process.

That’s why I’ve written this review on…

How to Thin Paint for Spray Guns

It’s a straightforward process that begins by purchasing the right paint, stirring it properly, dividing small amounts into a mixing container, adding the thinner, and final mixing.

The processes are repeated until you attain the targeted viscidity, and the thinning agent is contingent on the type of paint.

I’ve also discussed other topics related to the main title. They include:

- Agents used to thin paint for spraying

- The mixing percentages of paint and thinner for spray guns

- How to go about mixing paint for a spray gun

- The possibility of using acetone to thin paint

- How to operate a spray gun

- The distinguishing features between lacquer thinner and paint thinner

I urge you to equip yourself with the above knowledge to make the right purchases and follow the correct procedures.

I’ve sourced the information from personal experience, painting colleagues, online reviews, and clientele feedback.

So, if you are looking for questions regarding the above, rest assured you are in the right place.

Share this article’s links widely and return for more painting information.

I wish you the best painting experience ahead!